Innovation Can Pave the Way to Decarbonise High-temperature Heat in Industries

Newsletter

At this stage of the race toward the decarbonisation of our energy systems by 2050 we all agree that electricity is the main vector of the energy transition. The reason for that are threefold; first, wind and solar technologies have experienced a rapid cost reduction that make them competitive today; second, electricity is a high quality and versatile energy vector. Last, electrification enables the use of more efficient technologies, such as heat pumps or electric vehicles that consume one third of the corresponding legacy technologies.

Electricity can be transformed into mechanical energy, potential or thermal energy using existing conversion technologies, such as generators, pumps or electric heaters. These technologies should be sufficient to cover a large share of electricity needs that are automatically decarbonized if the supplied electricity comes from wind and solar.

However, electrification of the heating and cooling sector, which accounts for about half of global energy consumption and is responsible for more than 40% of energy-related carbon dioxide emissions, poses additional challenges. Today a large fraction of this consumption can be satisfied with mature and highly efficient technologies, i.e. heat pumps. But not all.

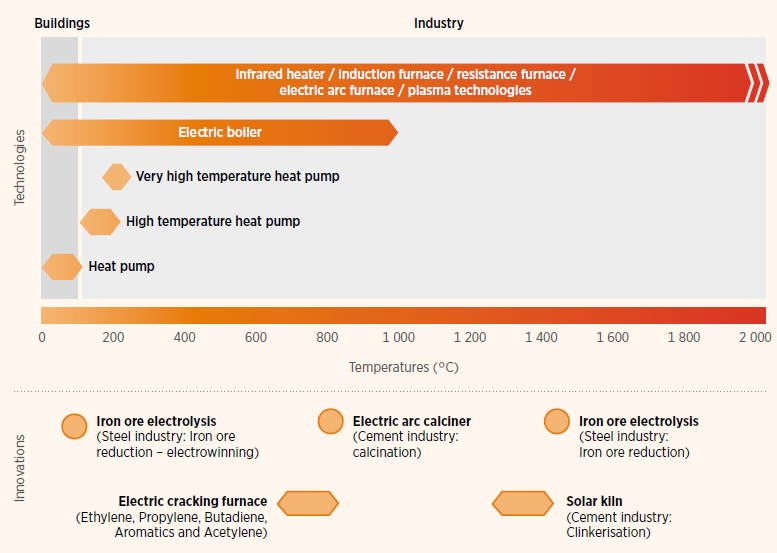

Industries, particularly energy intensive industries, require thermal energy to activate chemical reactions or physical transformations. These requirements do not only relate to energy quantities, but also to specific temperature levels that today cannot be reached by heat pumps, as desirable.

This means that new innovative solutions should be brought into markets to decarbonise industries. We can identify two main routes when it comes to decarbonising industries; one is the direct electrification of processes, the other, the indirect electrification of these processes by using green hydrogen, produced from wind and solar, as energy vector that can be used in replacement of natural gas. According to IRENA’s 1.5°C Scenario, by 2050, direct electrification could provide 27% of the industrial energy needs and hydrogen (indirect electrification) 22%, from today’s 23% both sources combined.

For heating applications with rages up to 200°C, efforts are focusing on expanding the temperature operation range of heat pumps. But the challenges in direct electrification arise from 200 °C up to higher than 1,000°C applications, and here is where some promising innovations are at different stages of developments today as elaborated in IRENA’s Innovation Landscape for Smart Electrification. Electricity for such very high temperature range can be used in electric furnaces, electric boilers or other electrolytic processes.

Three main industrial sectors – chemical, cement and steel – are the most challenging to electrify, and promising solutions are being developed for their processes. In the chemical industry, for example, fossil-based steam crackers operating at 700°C to 900°C are used to convert heavy hydrocarbons into lighter ones for production of high value chemicals. Electric-crackers (e-crackers), replacing conventional steam crackers, are now in the pilot phase. For example, Shell and Dow have installed an electricity-powered experimental heat steam cracker furnace unit at the Energy Transition Campus in Amsterdam (the Netherlands). This is a key milestone in the effort to decarbonise one of the most carbon-intensive processes of petrochemical manufacturing. The solution could be scaled up by 2025 if tests in 2023 show that it can successfully replace today’s gas-fired steam cracker furnaces. From other sectors, the cement industry is working on new kilns where heat is provided via plasma generators. The steel sector is piloting new electrolytic reduction processes. All using electricity as input energy carrier.

With the world approaching its first global stocktake of the Paris Agreement at COP28 in November, there is a huge amount of challenges industry and government have yet to discuss and explore being innovation at the core of this shared work.

To facilitate progress toward a decarbonised industrial sector, IRENA will be hosting several sessions at its Innovation Week which bring together leaders, experts, industry representatives and policy makers to discuss cutting edge innovations focused on speeding up the extremely deemed energy transformation via innovative solutions, including discussing on best ways to decarbonise industries.

If you want to contribute to the discussion and shape future actions, please request an invitation to IRENA’s upcoming Innovation Week, and attend the dedicated sessions happening on the 26th of September on solutions to decarbonise iron and steel sector, and the chemical and petrochemical sector.

More information can be found here: https://innovationweek.irena.org.